PRODUCT

DESIGN FEATURES

We offer a solution for every situation. Everything is tested by our qualified developers in a modern testing chamber. All products are custom-made and we are ready to meet your specific requirements for specific equipment or designs which are not listed here. Feel free to contact us.

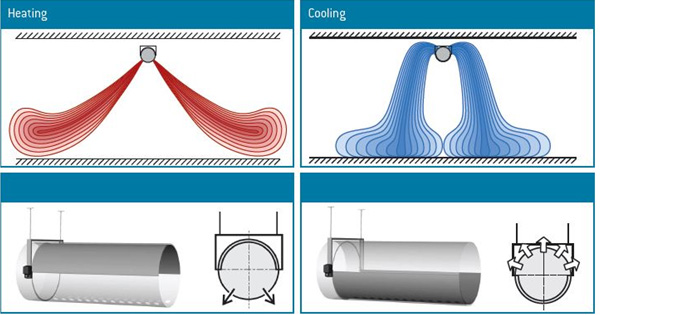

Membrace Diffuser

This combines two types of diffuser into one. The membrane flap is a lightweight non permeable material sewn all along the duct length. The membrane is attached to a two position motor. In heating mode the motor moves the membrane to cover the cooling diffusers located at the top of the duct, the supply air exits the heating perforations on the bottom of the duct. In cooling mode the motor moves the membrane to cover the heating perforations at the bottom of the duct and the cool supply air leaves the perforations at the top of the duct. The membrane allows two totally different diffusion styles in one duct.

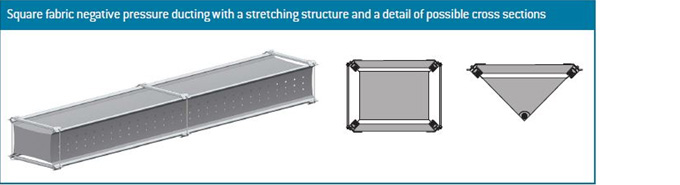

Negative Pressure Ducting

We supply these only in square or triangular cross-sections. Because taught fabric is essential for extract ducting we tension the walls using a combination of suspension profiles, tensioning bolts and threaded bar. Air is drawn into the duct through perforations that can be positioned on any side and anywhere along the length of the duct. To ensure equal extract rates we can adjust the perforation diameters or the gaps between the perforations progressively along the duct. We anticipate our negative pressure ducts will be used where regular and/or thorough cleaning is required. Negative pressure fabric ducting is easily disassembled from the suspension system and unzipped into smaller washable parts. If the NMI material is used (containing a silver nanolayer), the ducting is antibacterial

IMPORTANT NOTE : Foe fabrics NMS, NMI, NMR only

Insulated Ducting

Used for decreasing temperature loss during transfer of conditioned air to the diffusers. A 40mm thick, loose fibre, insulating polyester material is sewn between two layers of fabric ducting material. All of our fabric ducting materials are available for use as the outer layer of the insulated duct allowing an easy match with other parts of the system. The manufacturing process compresses the original 40 mm loose insulation layer by 20 mm, reducing the finished product wall thickness. The maximum duct heat transfer coefficient is 1.8 W/m2/K. Insulated duct is manufactured as standard in 2000 mm zipped lengths and starts from Ø250 mm upwards. Insulated ducting also acts as an excellent noise dampener, absorbing and reducing in duct noise vibration, contact us for specific details.